2006 year,We are studying and practicing, accumulating and exploring......

2009 year,Successively establish XIEBANG ALUMINUM and BORUISI(SHANGHAI)ALUMINUM TECHNOLOGY CO.,LTD Operates various mold making and production, aluminum extrusion and processing, aluminum deep processing

2012 year, Company expands deep processing AND vacuum welding、Friction welding

2013 year, Established by SHANGHAI MARIGOLD INTERNATIONAL TRADING CO.,LTD Expand the international market, the products are exported to the world.

BY 2022, Our company's export value reached $ 37 million,

The company has 28 CNC machined centers (3-axis, 4-axis, 5-axis), two sets of brazing furnaces (fully welded with imported solder) three coordinatedetectors,

Acoustic wave detectors, and projection detection equipment. It is equipped with a number of skilled programming engineers in CNC machining, and the processing length can reach 6.5 M.

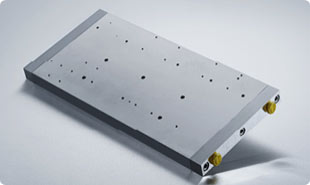

Our company's main business: Vacuum welding, diffusion welding, friction welding, aluminum water cold plate (aluminum, copper, stainless steel),

aluminum high -precision vehicle milling, CNC aluminum processing, mold manufacturing, aluminum extrusion, etc. Essence

Vacuum Brazed, the perfect connection of metal and metal, while maintaining the light and cleaning of the components. Unlike tin welding or other welding, even complex shapes can be welded without any deformation.

The furnace profile specifies the temperature, vacuum level, and cycle time. Brazing of cold plates and heat exchangers usually takes place at approximately +598° , the profile depends in large part on alloys selected, total mass in the furnace, and the vacuum furnace being used. The furnace controller monitors vacuum levels and temperatures and automatically advances to the next segment as programmed in the recipe until the cycle is complete.

Aliminum brazing

Stainless steel brazing

Copper brazing

Carbon steel brazing

Nickel alloy brazing / Tantalum brazing

Titanium brazing / Molybdenum brazing

Diffusion Welding (Aluminum, Copper)

Brazing / Annealing

Hardening & Tempering

Age Hardening

Low Pressure Carburizing

Nitriding / Homogenizing

Hydriding / Dehydriding

Diffusion Bonding / Stress Relieving

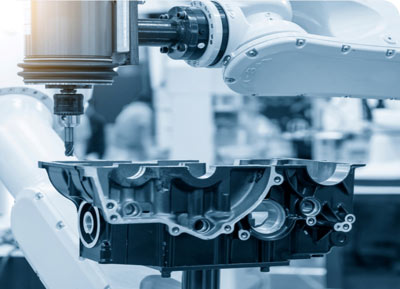

Our precision CNC machining services can manufacture complex finished parts and assemblies,

Our standard tolerance is +/-0.01mm for most commercial and industrial applications,

If you need smaller tolerances for special projects, please consult us.

CNC milling creates complex prismatic shapes and planes for

avariety of commercial and industrial products,

How can we support your most rigorous CNC milling project with

multi axis CNC linkage processing,

And it is not limited by quantity and region.

Five axis linkage processing center

Vertical Dragon Gate Machining Centers

Work size: 810X1000mm

Working platform size: 550X2500~6500mm

Repeated positioning accuracy: +/-0.008mm

Materials:

Aluminum, steel, copper, stainless steel, titanium alloy, carbon fiber, polymer, etc.

YOU HAVE TOO HIGH DEMAND FOR THE PRODUCT, WE HAVE A COMPREHENSIVE SUPPLY CHAIN AND SOLUTION.

3 & 4 Axis Vertical Machining Centers

Work size: 600mmX600mm/400mm

Work size: 1100mmX2200mm/800mm

Repeated positioning accuracy: +/-0.007mm

Materials:

Aluminum, steel, copper, stainless steel,

Titanium alloy, carbon fiber, polymer, etc.

YOU HAVE TOO HIGH DEMAND FOR THE PRODUCT, WE HAVE A COMPREHENSIVE SUPPLY CHAIN AND SOLUTION.

CNC car milling composite Machining Centers

Work diameter: 390mm/168mm, 570/278mm

Work length: 330mm/630mm, 780/1530mm

Processing accuracy tolerances: +/-0.004mm

Materials:

Aluminum, steel, copper, stainless steel,

Titanium alloy, carbon fiber, polymer, etc.

YOU HAVE TOO HIGH DEMAND FOR THE PRODUCT, WE HAVE A COMPREHENSIVE SUPPLY CHAIN AND SOLUTION.