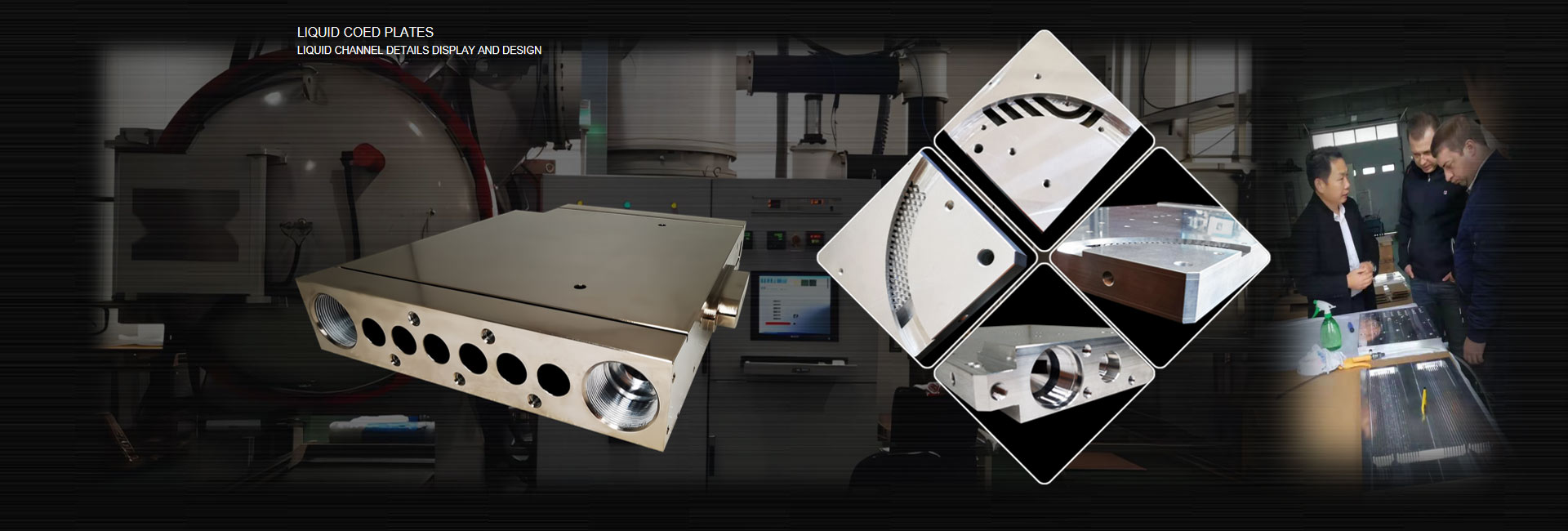

As our requirements for accuracy and reliability of medical equipment become higher and higher, heat dissipation control becomes more important. Here we believe that water cooling will be a mainstream trend, and the precise core cooling head will occupy a smaller area. Water cooling can control the heat dissipation from the remote, so that the noise is reduced and the heat dissipation performance is also improved.

For the understanding and analysis of the three major application areas of medical equipment: detection, treatment, and auxiliary, our requirements for radiators are defined as: high performance, long life, and stable quality, so as to meet the particularity of normal operation of medical equipment. Will not cause downtime and failure of the entire device (set) due to heat dissipation problems

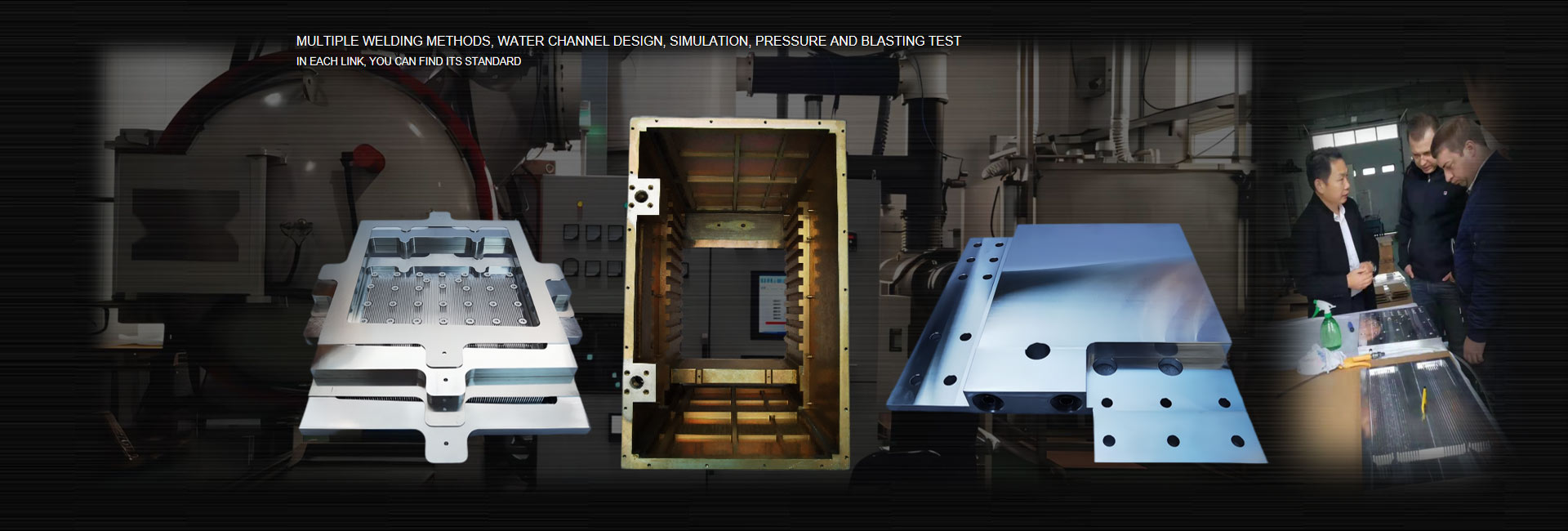

The heat sink of the main control board of the inspection equipment adopts the combination of aluminum base plate, copper boss, copper duct, copper buckle gear, and turbo fan to solve the heat dissipation requirement of the main board. The base plate, boss, duct and gear are combined. The use of lead-free soldering technology enables these accessories to be combined steadily and firmly, which not only ensures the high efficiency of the hot channel, but also takes into account the environmental protection that the industry now attaches importance to. The high conductivity of copper is used to quickly take away from the heat source. Heat, through the high thermal balance of the heat pipe, quickly transfers heat to the heat sink, and then uses the high wind pressure characteristics of the turbo fan to force the heat from the heat sink to be absorbed by the strong air flow to ensure that the motherboard can be in a safe and constant temperature It can work effectively under the condition of normal use, and provide safety guarantee for heat dissipation for patients in normal use of equipment.