Aluminum alloy machining is also called parts machining or CNC finishing, automatic lathe machining, CNC lathe machining, etc.

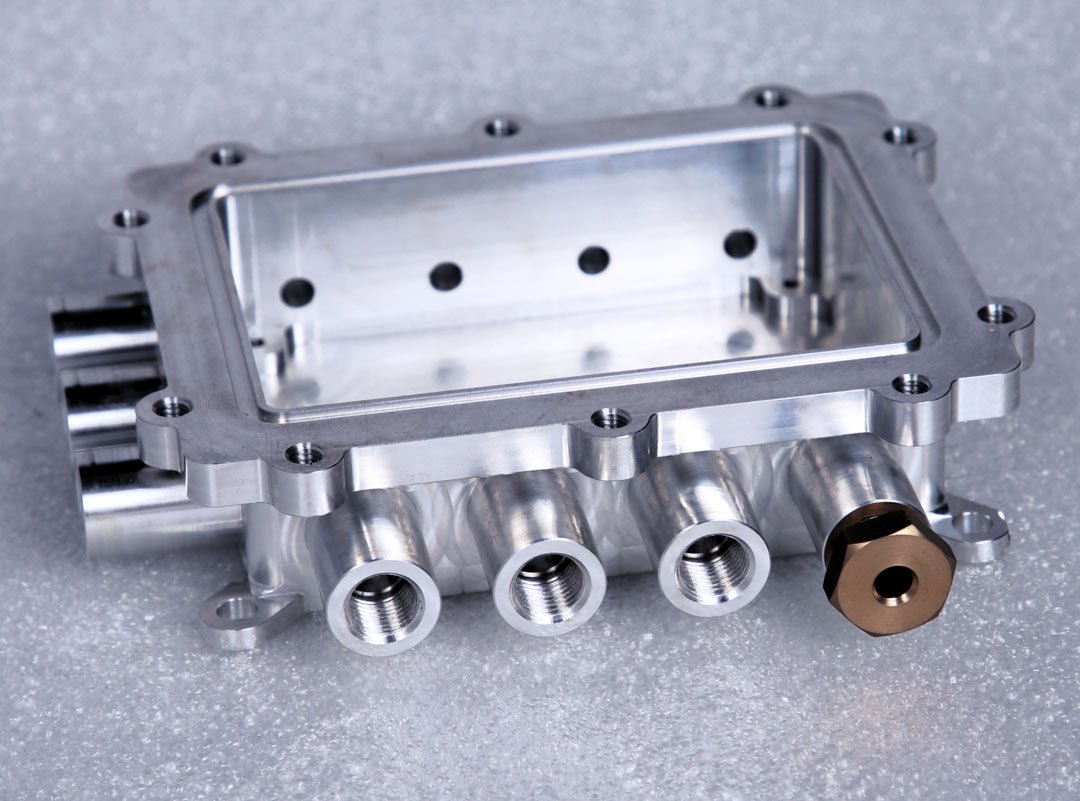

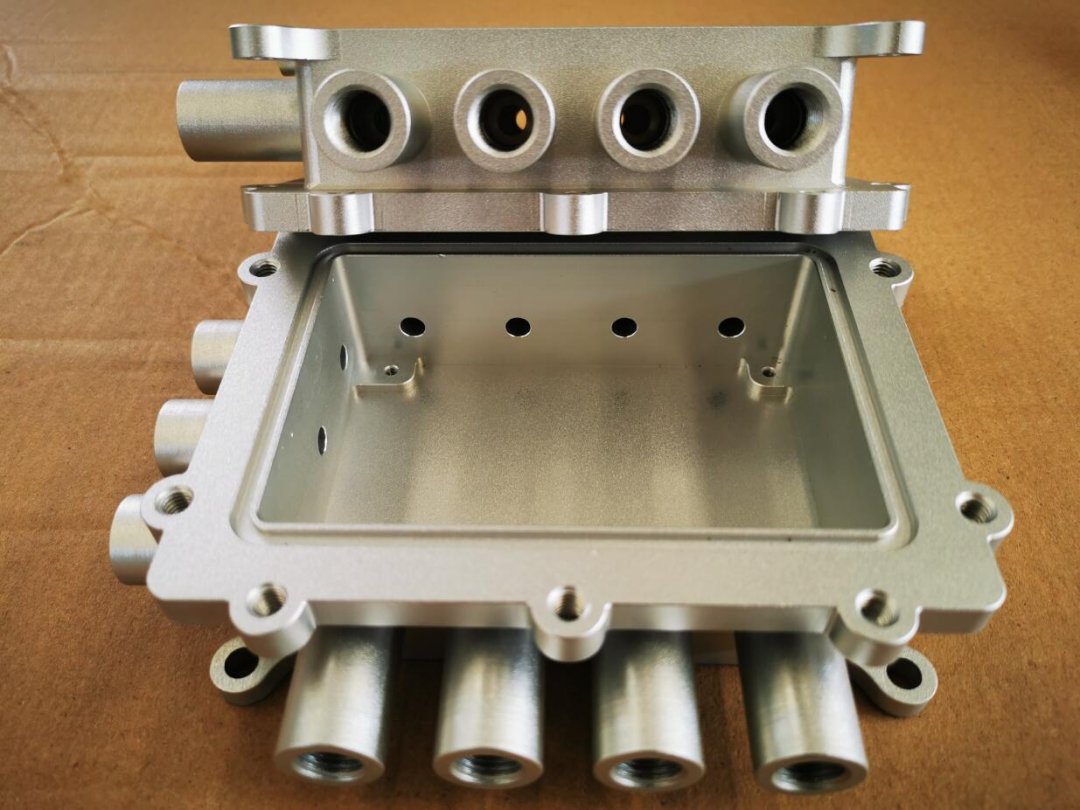

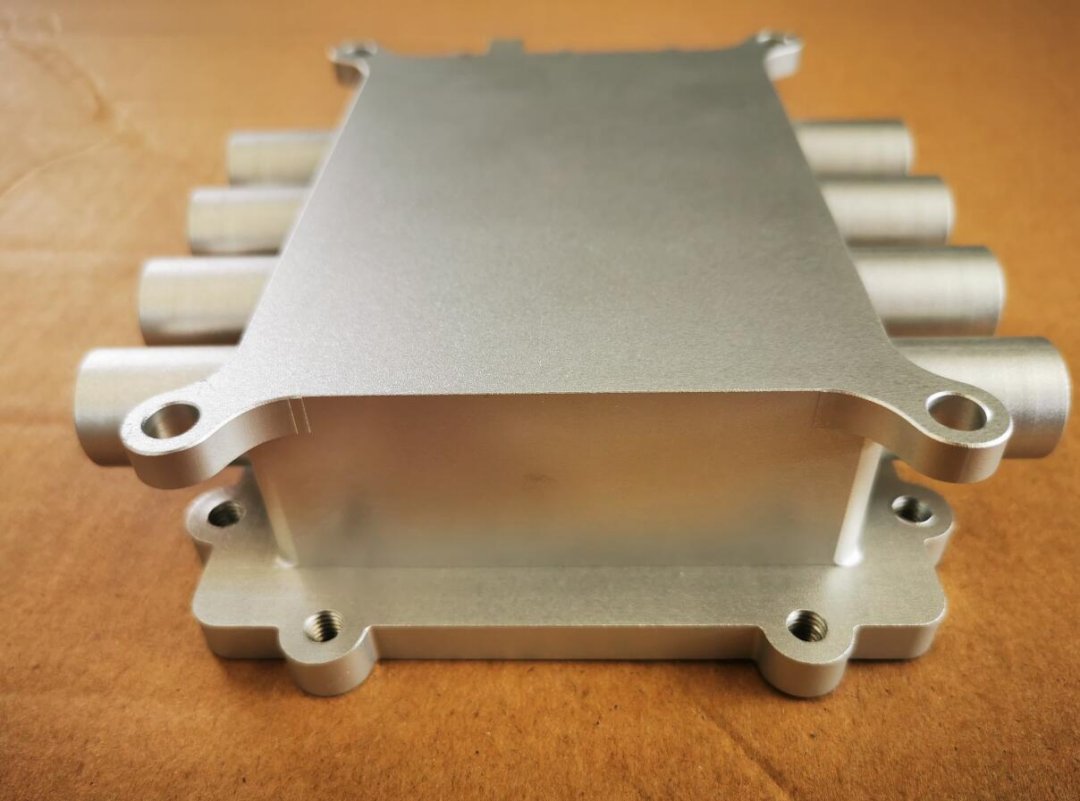

Use general-purpose machine tools such as turning, milling, planing, drilling, grinding, etc. to process mold parts, and then perform necessary fitter repairs. Mold parts with high precision requirements must be processed by precision machine tools CNC, in order to make mold parts especially complex shapes The processing of punches, concave model holes and cavities is becoming more automated, reducing the workload of fitter repairs, and it is necessary to use CNC machine tools (such as three-axis CNC milling machines, machining centers, CNC grinding machines, etc.) to process mold parts.

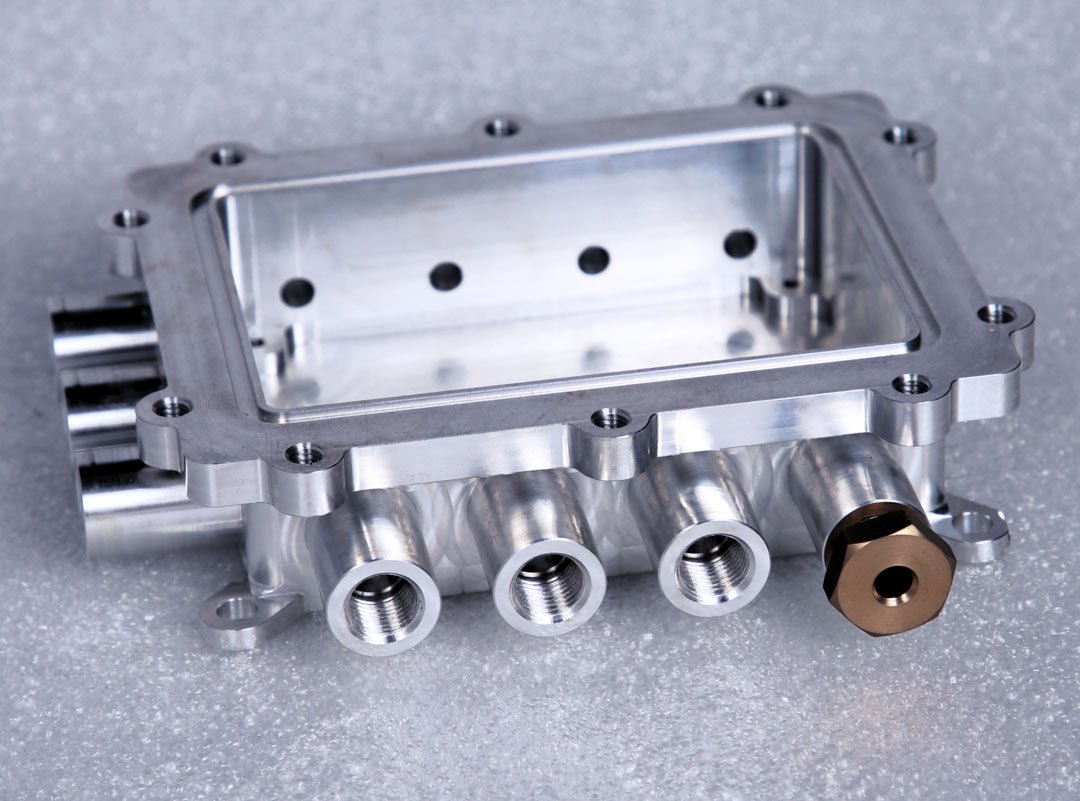

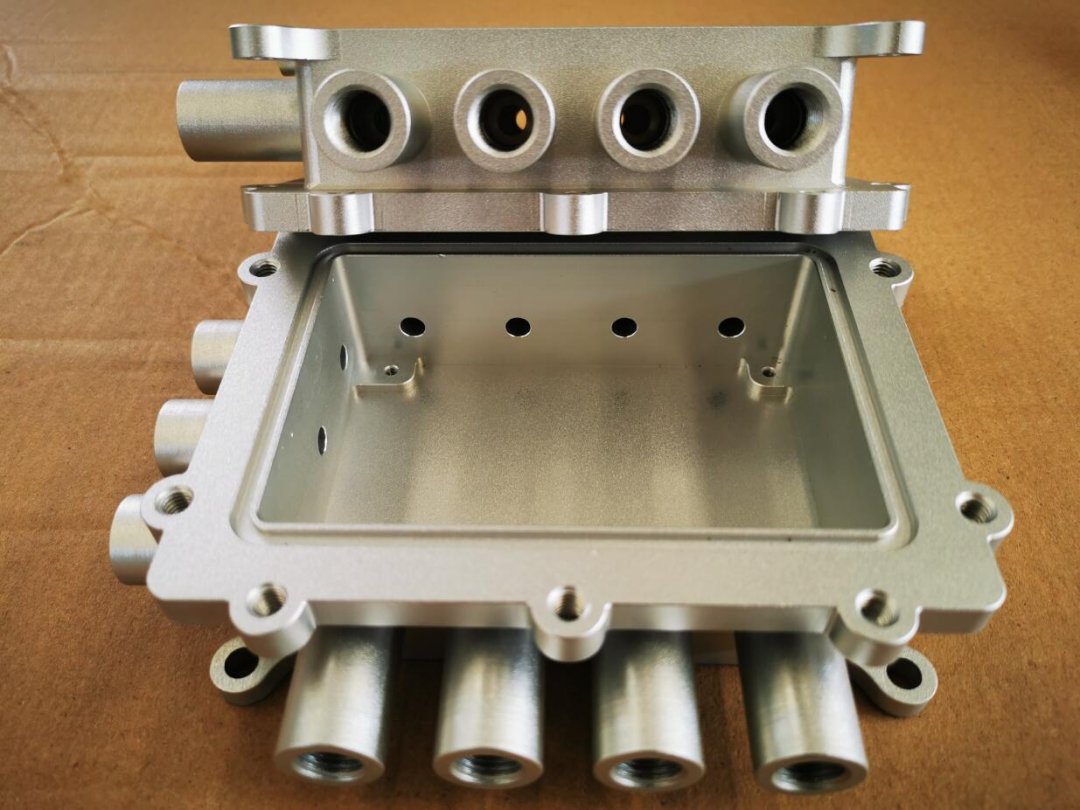

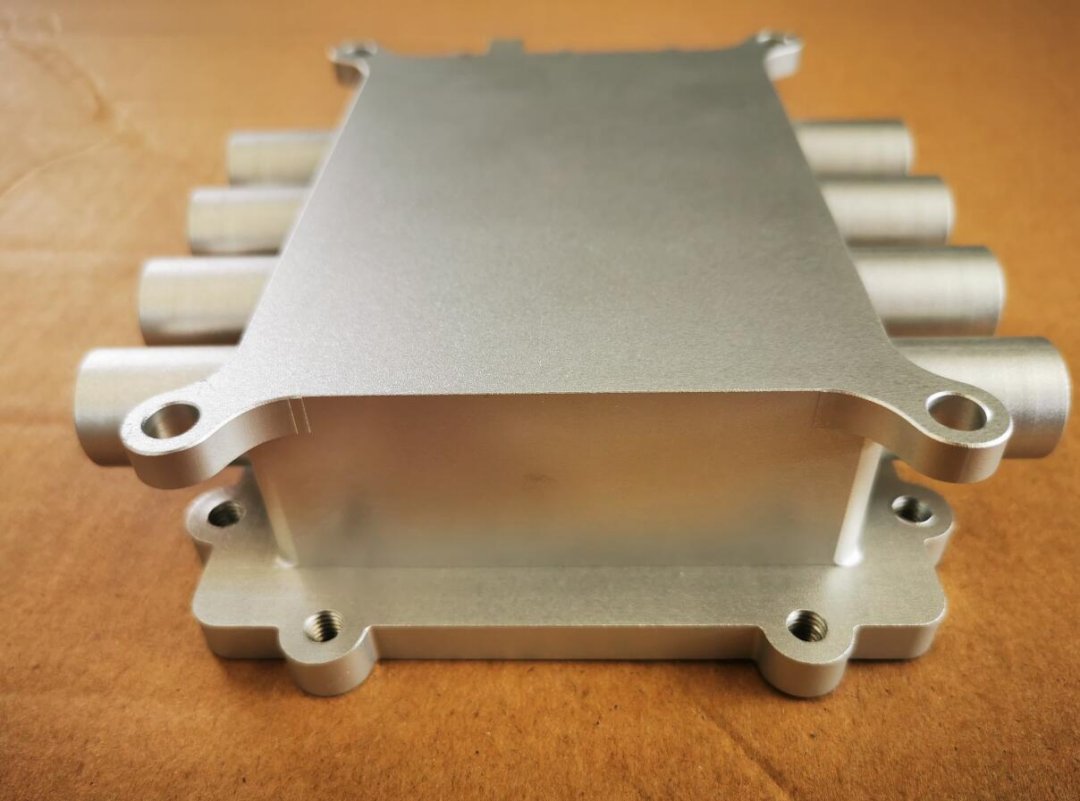

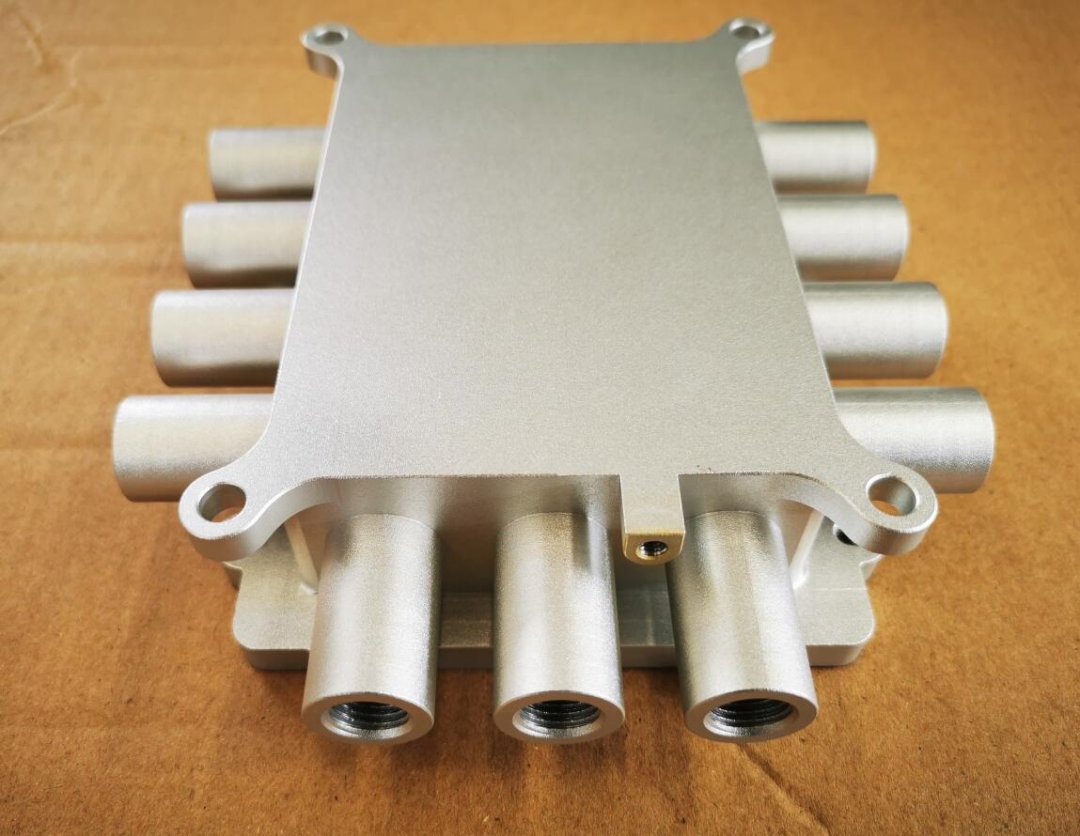

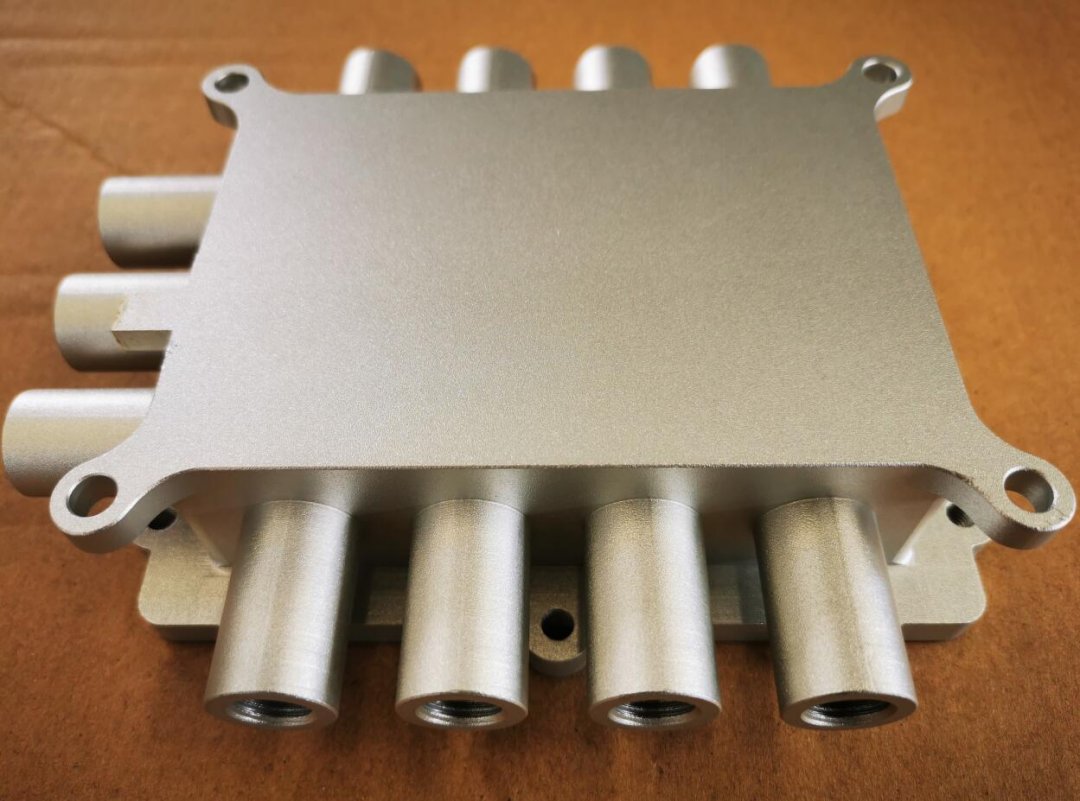

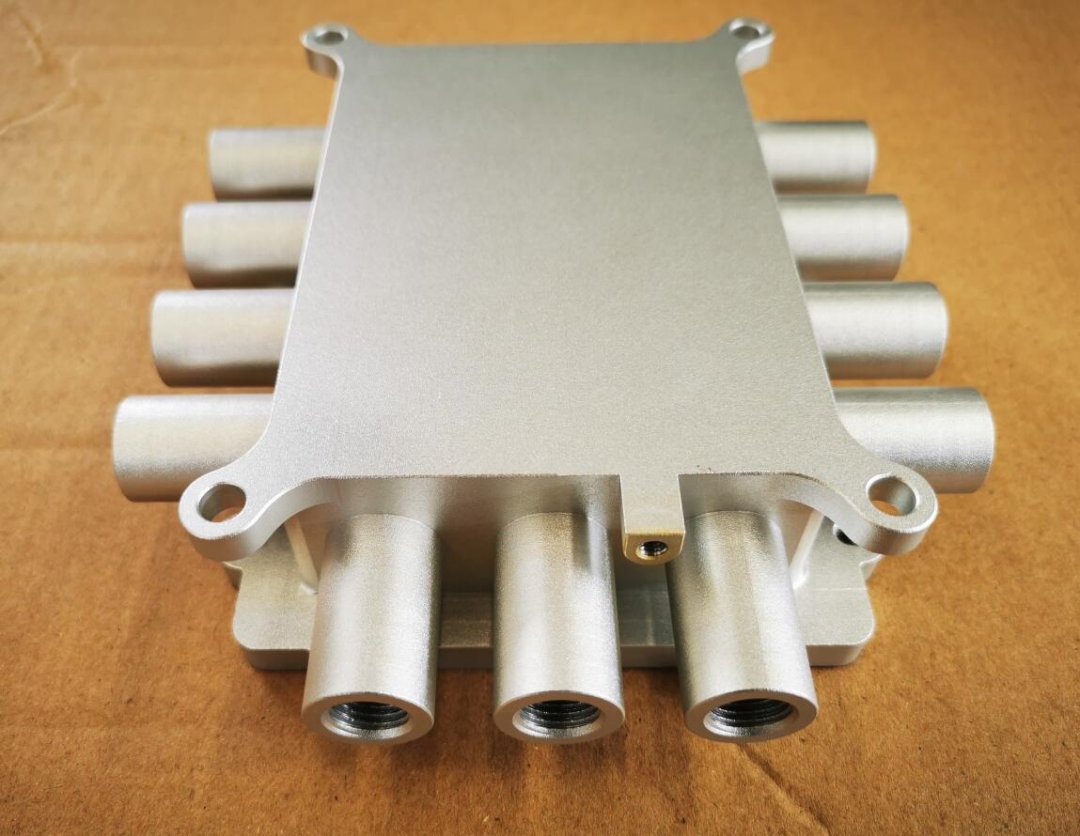

Due to the excellent characteristics of a series of aluminum alloy materials, they have been widely used in various fields of the national economy. Our company's main CNC machining is mainly aluminum 6061, 6063, 6070 or better quality aluminum 7075, 7175, 7079, etc., which are widely used In industries such as aerospace, rail transit, electronic communications, data centers, smart grids, building decoration, packaging containers, machinery and electrical, petrochemical, energy power, home appliances, hardware, etc.,

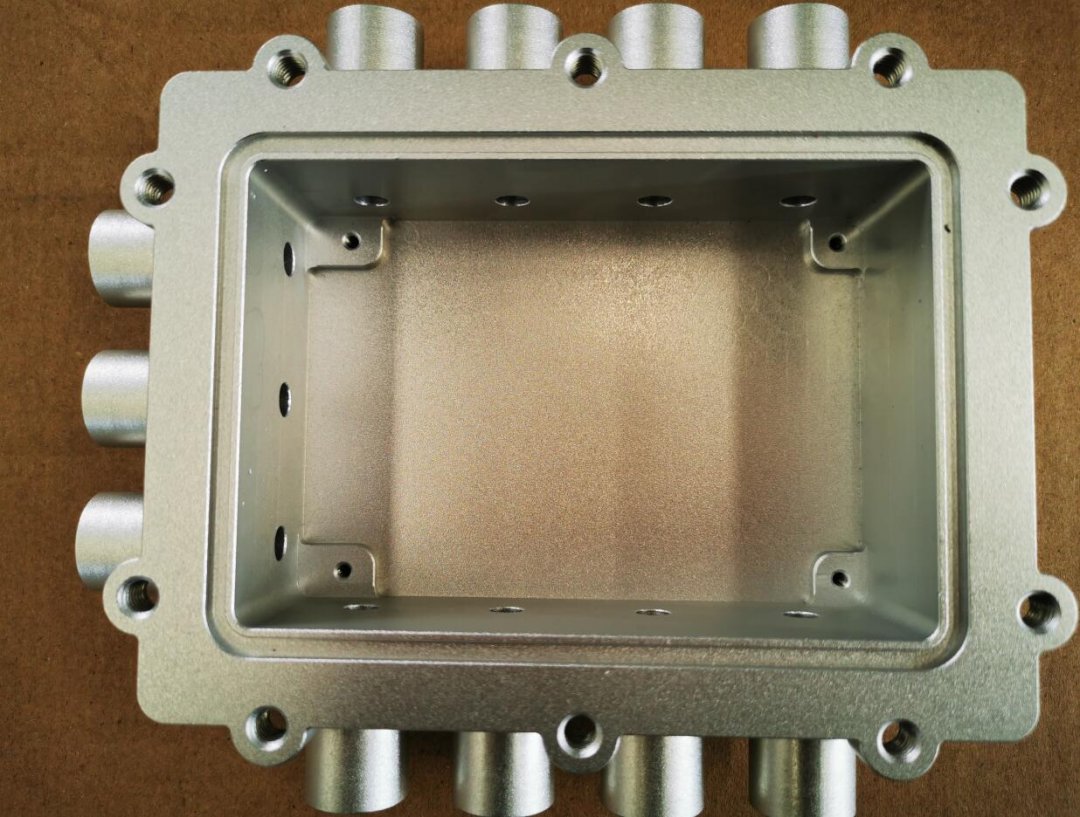

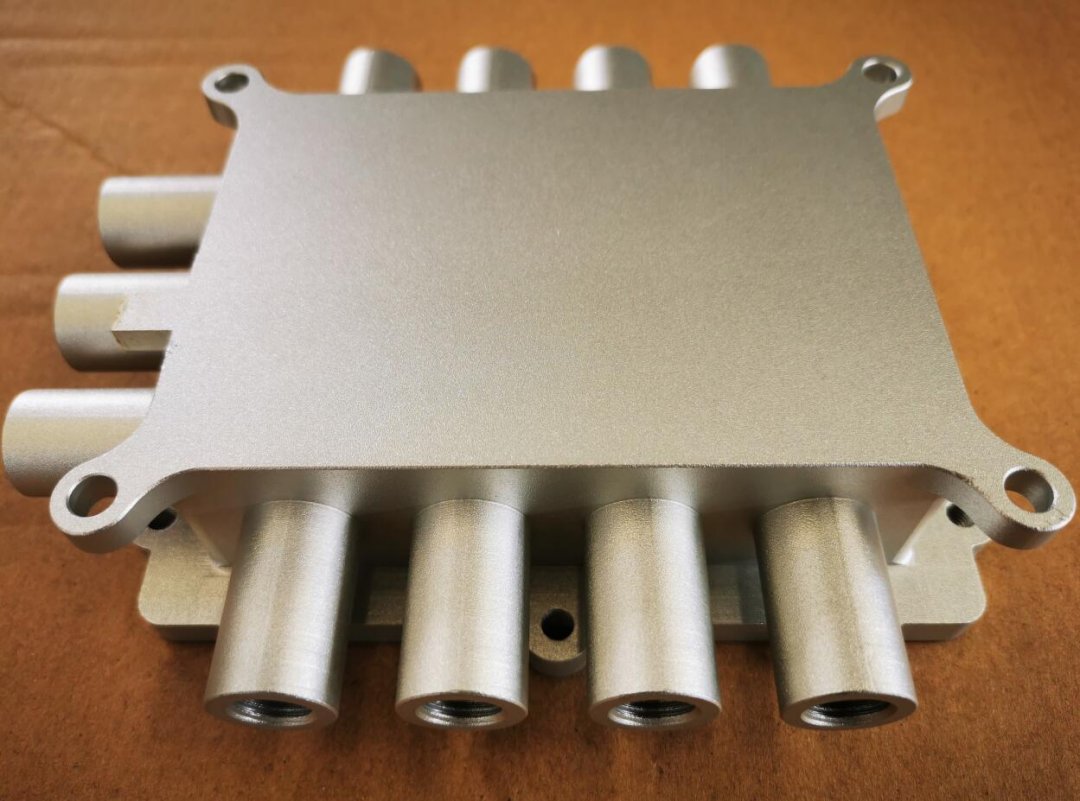

The meaning of precision machining is to increase durability during use, improve material quality and parts accuracy, increase durability during use, improve mechanical quality and have high-precision interchangeability, and the effect of precision machining can increase the zero-dimensional accuracy of the machine. Assemble machinery with parts, it is possible to perform smooth motions with less sway, and exert its functions. The direct or indirect effect can increase the wear resistance of parts.

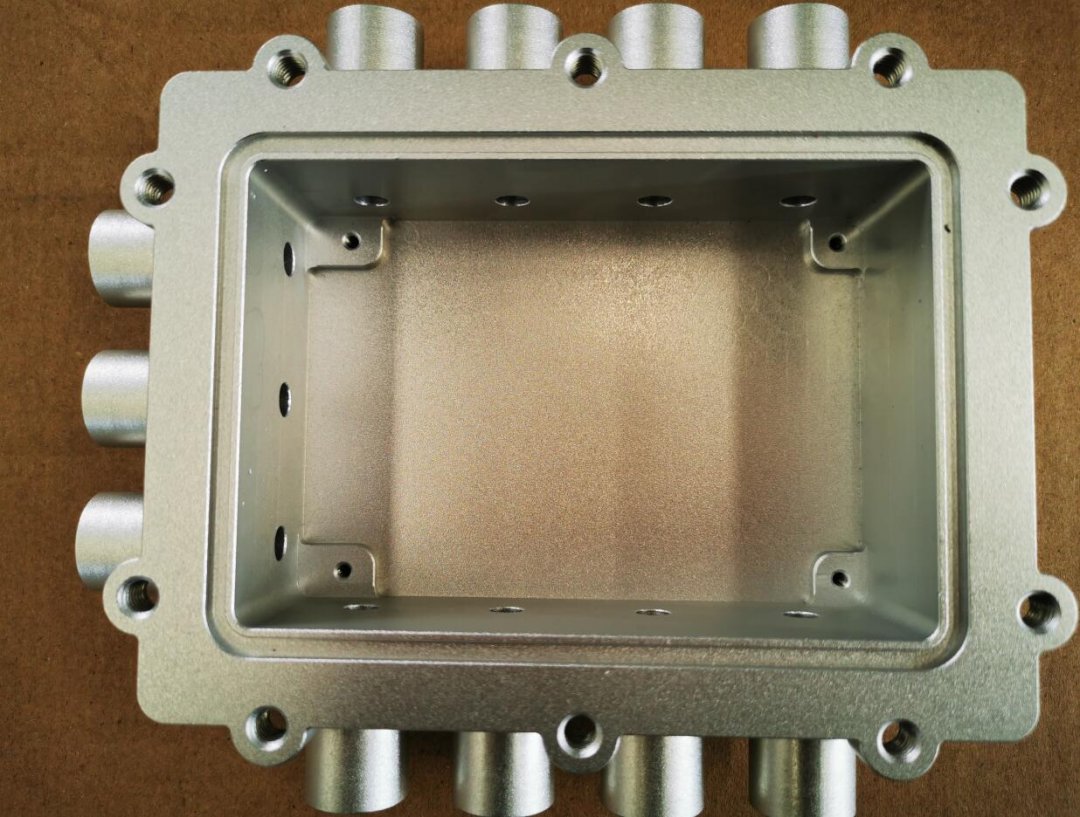

Our company's precision machining process is summarized: extrusion molding, rough milling, fine milling inner cavity, fine milling arc surface and side surface, product surface polishing, arc bending, banknote spraying, wire drawing, oxidation, inspection, coating, delivery,