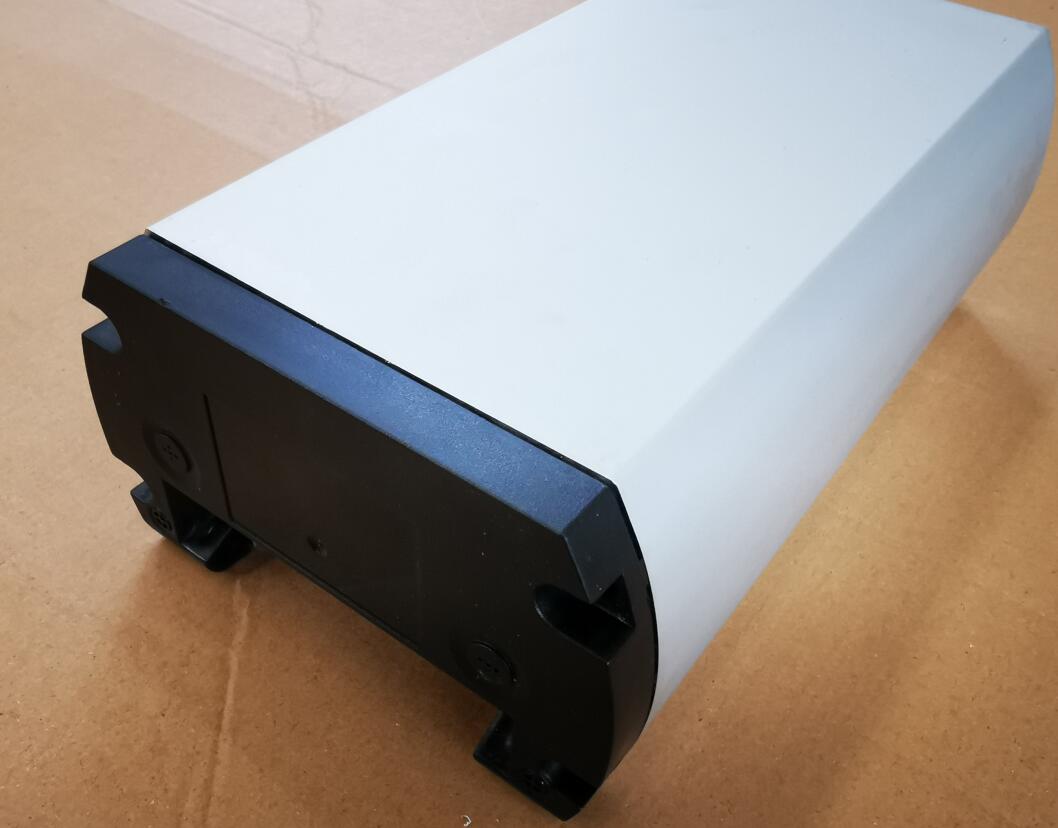

The production process of non-standard aluminum profile aluminum profile includes three processes: casting, extrusion and oxidation.

1. Melting and casting are the first process in the production of aluminum profiles.

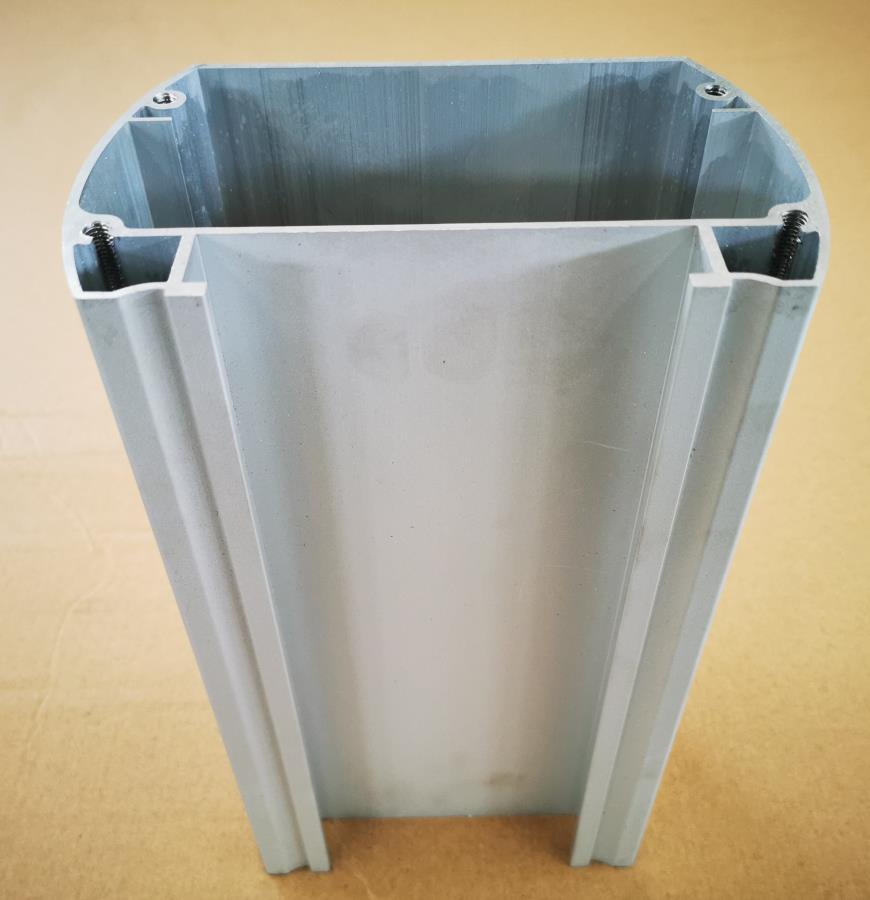

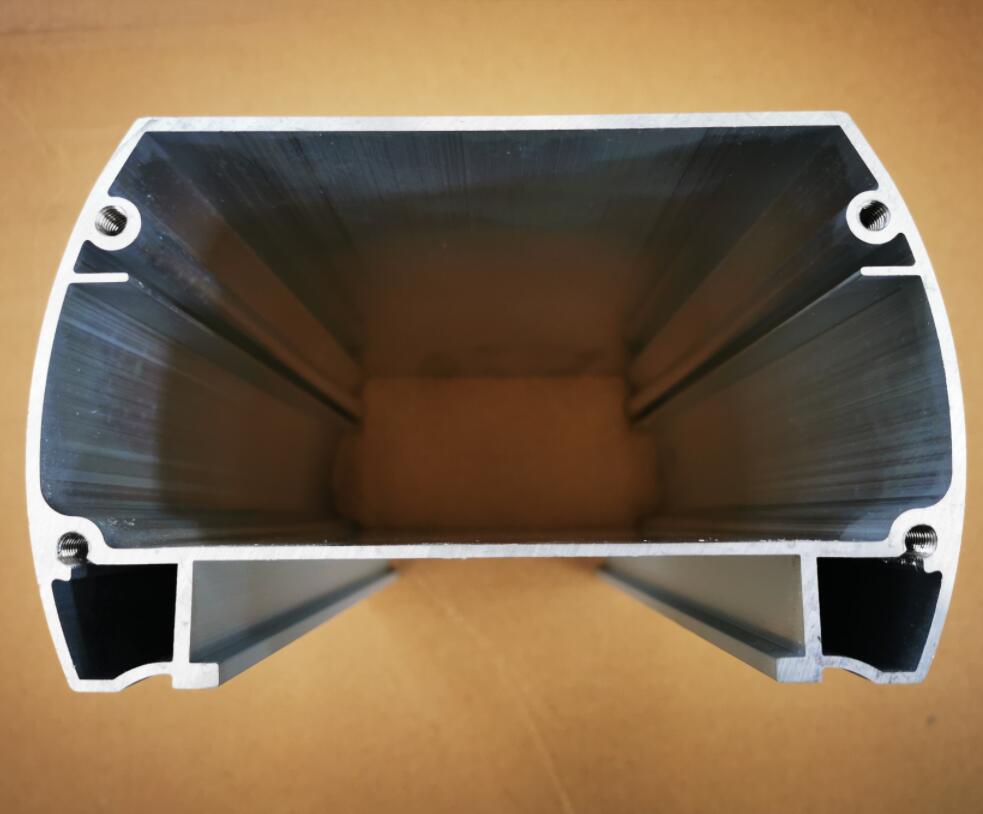

2. Extrusion and extrusion are the means of forming aluminum profiles. First, design and manufacture a mold according to the section of the aluminum profile product, and use an extruder to extrude the heated round cast rod from the mold. Our company commonly uses The grade of aluminum alloy is 6063. The heat treatment is completed by air-cooling and artificial aging during extrusion. The heat treatment system of different grades of alloy is different.

3. Oxidized and extruded aluminum profiles have poor surface corrosion resistance. Surface treatment must be carried out by anodic oxidation to increase the corrosion resistance, wear resistance and appearance of aluminum.

(1) Surface pretreatment: Use chemical or physical methods to clean the surface of the profile and expose the pure matrix to facilitate obtaining a complete and dense artificial oxide film. It is also possible to obtain mirror or matt (matt) by mechanical means,

(2) Anodizing: The surface pretreatment of the profile will undergo anodization on the surface of the substrate under certain process conditions to form a dense, porous, and strong adsorption Al2O3 film.

(3) Sealing: sealing the pores of the porous oxide film formed after anodic oxidation to enhance the anti-pollution, corrosion resistance and wear resistance of the oxide film. The oxide film is colorless and transparent. Using the strong adsorption of the oxide film before sealing, some metal salts are adsorbed and deposited in the film pores, which can make the appearance of the profile show many colors other than the natural color (silver white), such as: black, bronze, Golden yellow and stainless steel color, etc.

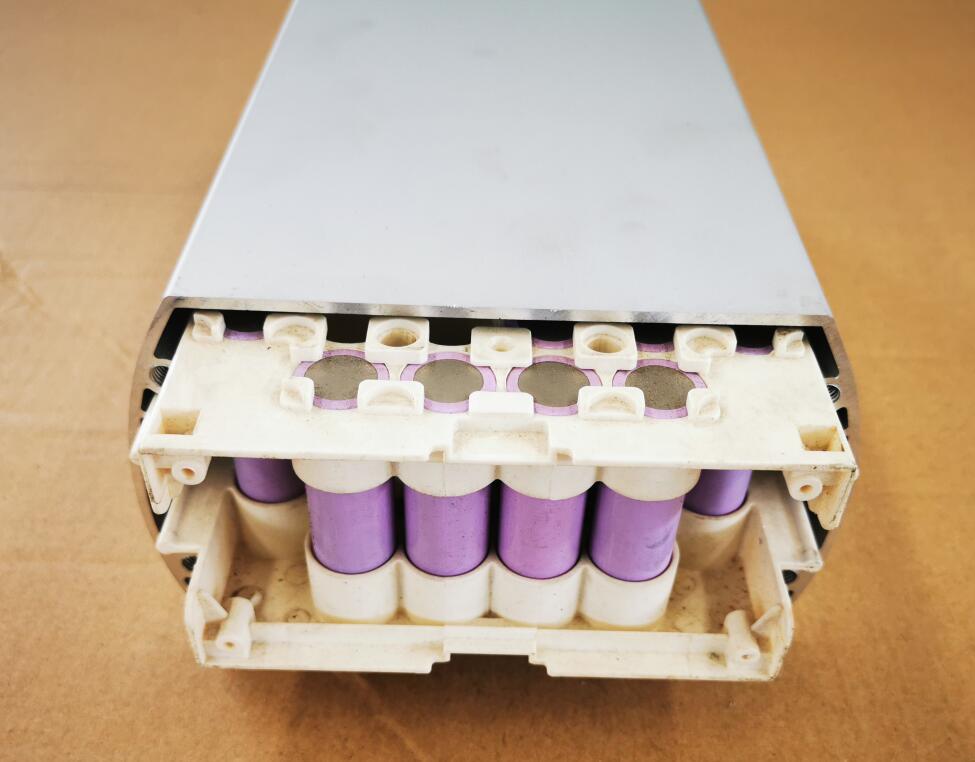

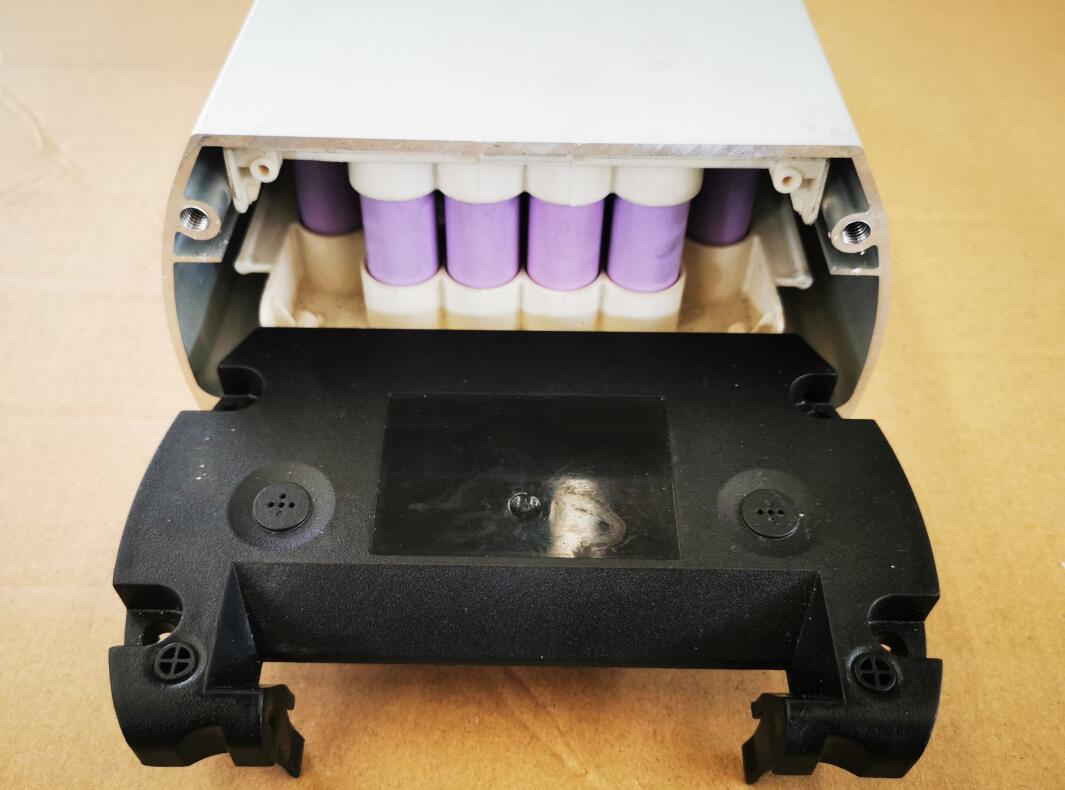

Due to the excellent characteristics of a series of aluminum alloy materials, they have been widely used in various fields of the national economy. Our company's main CNC machining is mainly aluminum 6061, 6063, 6070 or better quality aluminum 7075, 7175, 7079, etc., which are widely used In industries such as aerospace, rail transit, electronic communications, data centers, smart grids, building decoration, packaging containers, machinery and electrical, petrochemical, energy power, home appliances, hardware, etc.,

The meaning of precision machining is to increase durability during use, improve material quality and parts accuracy, increase durability during use, improve mechanical quality and have high-precision interchangeability, and the effect of precision machining can increase the zero-dimensional accuracy of the machine. Assemble machinery with parts, it is possible to perform smooth motions with less sway, and exert its functions. The direct or indirect effect can increase the wear resistance of parts.

Other surface treatment processes of our profiled materials:

Aluminum alloy electrostatic spraying, aluminum alloy paint, aluminum alloy zinc plating, aluminum alloy chromium plating, aluminum alloy nickel plating, aluminum alloy titanium plating, aluminum alloy gold plating, aluminum alloy silver plating, aluminum anodizing, aluminum alloy infiltration, aluminum alloy spraying , Aluminum alloy sandblasting oxidation, aluminum alloy black dyeing, aluminum alloy cold electroplating, aluminum alloy Teflon treatment, etc.,