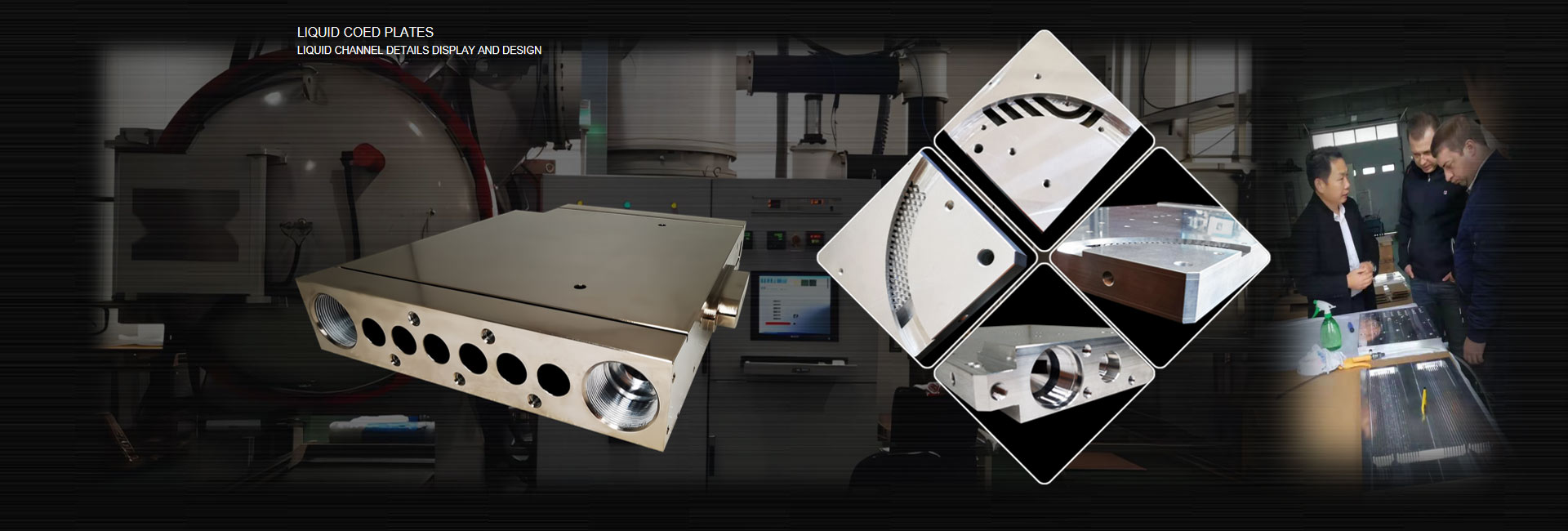

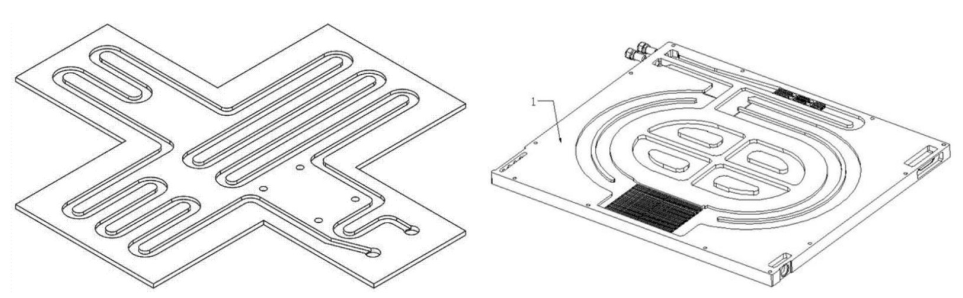

The temperature rise of the rotor and bearing in the wind turbine is the problem of the large-size water-cooling plate of the wind power module. The surface of the base plate of the water-cooling plate is provided with rectangular parallelepiped grooves in rows, and multiple sets of fin-type heat dissipation units are respectively arranged in the rectangular parallelepiped recesses. In the tank, a plurality of distribution tables are respectively arranged in the rectangular parallelepiped groove and between adjacent fin-type heat dissipation units. The water inlet and outlet joints are respectively arranged at both ends of the substrate, and the two ends of the substrate are respectively provided with inlet sinks and The outlet sinking table and the inlet sinking table are respectively connected with the water inlet joint and the front-end fin-type heat dissipation unit, the outlet sinking table is respectively connected with the outlet joint and the tail-end fin-type heat dissipation unit, and the fiber material board and the cover plate are sequentially arranged on the surface of the substrate. The internal flow channel structure of the water-cooling plate is excellent, and it has higher heat dissipation efficiency. Under the premise of meeting the same heat dissipation index, the heat dissipation effect is more uniform, and the pressure drop of the water cooling system can be minimized to ensure the uniformity of multiple sets of power modules. Temperature performance and stable operation of wind power system,

Under different cooling water flow conditions, the performance of the panel-tube photovoltaic (PV/T) system will change significantly. The article tested the changes in the temperature, power generation, cooling water temperature of the plate and tube PV/T module, and the thermal efficiency of the plate and tube PV/T system when the cooling water flow rate changes (0~0.25 kg/s) through experiments. . The analysis results show that when the cooling water flow rate is 0~0.25 kg/s, the average value of PV/T module power generation is about 5% higher than that of PV module. At the same time, the thermal efficiency of PV/T system can reach about 57%; The power generation of the tubular PV/T module decreases with the increase of the temperature of the PV/T module, and the thermal efficiency of the PV/T system increases with the increase of the cooling water temperature.